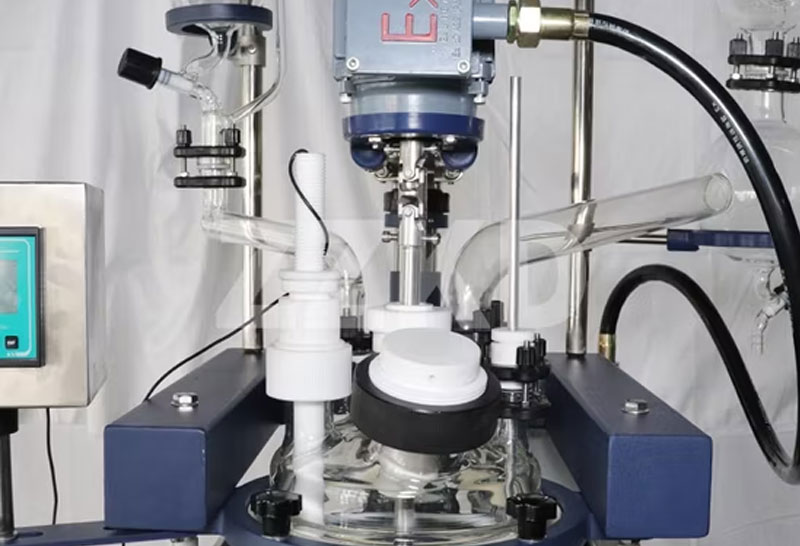

Our integrated manufacturing units are equipped to handle complex, multi-step synthesis processes with utmost efficiency and safety. We specialize in the production of a broad spectrum of chemical compounds, including:

| Reactors | Glass-lined, stainless-steel and MS reactors ranging from 500L to 12,000L |

| Hydrogenators | SS limpet coil hydrogenator up to 6000L |

| Crystallizers | SS, MS crystallizers ranging from 2000L to 6000L |

| Temperature Range | Capable of operating from -20°C to 250°C |

| Pressure Range | Up to 15 bars |

| Separation Equipment | High-speed centrifuges of up to 48 inches; Agitated Nutsche Filters (ANF), Filter Nutsche of SS, MSRL up to 5000L |

| Drying Units | Rotary Vacuum Dryers (RVD), Tray Dryers |

| Distillation Columns | For high-purity solvent recovery and separation |

| Specialized Setups | Hydrogenation, Nitration, Oxidation, Hydrolysis, and Acidification systems |

At Dhanlaxmi Chemicals, environmental preservation is not just a policy—it is a fundamental commitment that we uphold uncompromisingly across all our operations.

Our Effluent Treatment Policy ensures that all liquid waste is treated effectively and disposed of in an environmentally responsible manner. Effluents undergo primary treatment within our premises, followed by safe disposal to the ISO 14000-certified Common Effluent Treatment Plant (CETP) operated by the Nandesari Industries Association (NIA), in full compliance with applicable environmental regulations.

| On-site Primary Treatment | Effluents are first treated internally through robust processes that neutralize and reduce harmful components. |

| Certified Disposal | Capable of operating from -20°C to 250°C |

| Flue Gas Treatment | Flue gases generated from our boiler systems are passed through bag filters and water scrubbers to effectively capture particulates and neutralize harmful gases, thereby preventing atmospheric pollution. |

| Strict Compliance | All disposal practices align with local, state, and national environmental standards and guidelines. |

| Continuous Monitoring | Effluent quality is regularly tested and monitored to ensure regulatory compliance and environmental safety. Real-time monitoring of effluent parameters (BOD, COD, TDS) |

| Commitment to Sustainability | We actively pursue initiatives that reduce waste generation, promote recycling, and support long-term sustainability goals. |

To ensure uninterrupted and efficient plant operations, we have established a robust utility infrastructure that supports a wide range of chemical processes across our manufacturing units.

Our utilities are designed to maintain process consistency, energy efficiency, and operational safety at every level.

| Steam | Steam boilers of 2000kg/hr and 800kg/hr, also additional steam is sourced from the centralized steam house of Nandesari, ensuring continuous and reliable steam supply during peak demand. |

| Chilling and Cooling | cooling towers up to 200TR capacity, chilling plant |

| Compressed Air, Vacuum, and Nitrogen Systems | |

| Hydrogen Gas Station | |

| Power backup for critical operations and uninterrupted water supply | |

These systems allow for operational continuity and high process reliability across all units.

Our storage and logistics infrastructure is designed to ensure the safe, efficient, and compliant handling of raw materials, intermediates, and finished products throughout the supply chain.

We follow best practices in material management, segregation, and traceability to maintain product integrity and meet regulatory and customer-specific requirements.

| Dedicated Warehousing | Separate storage areas for raw materials, in-process goods, and finished products, Fire-fighting systems and safety protocols in place for handling hazardous materials |

| Bulk Storage Facilities | SS and MS storage tanks for solvents and corrosive chemicals |

| Safe Handling & Packaging | Drum filling stations, IBC handling, and palletized storage. Customized packaging solutions as per domestic and international shipping requirements |

| Inventory Management | Digitized systems for real-time tracking, batch traceability. Regular audits and documentation to ensure full compliance with GMP and ISO norms |

| Logistics Support | Well-connected dispatch area for seamless transport coordination |

Our storage infrastructure is built to ensure not only operational efficiency but also the highest standards of safety and compliance.